Sometimes we have amazing ideas for products but as soon as we think of how complicated the manufacturing process may be, we immediately give up on them. This is both a good and a bad thing at the same time. It’s a bad thing because most of those ideas may have ended to be extremely successful, and the good thing is that we learn about the importance of having a reliable contract manufacturing partner.

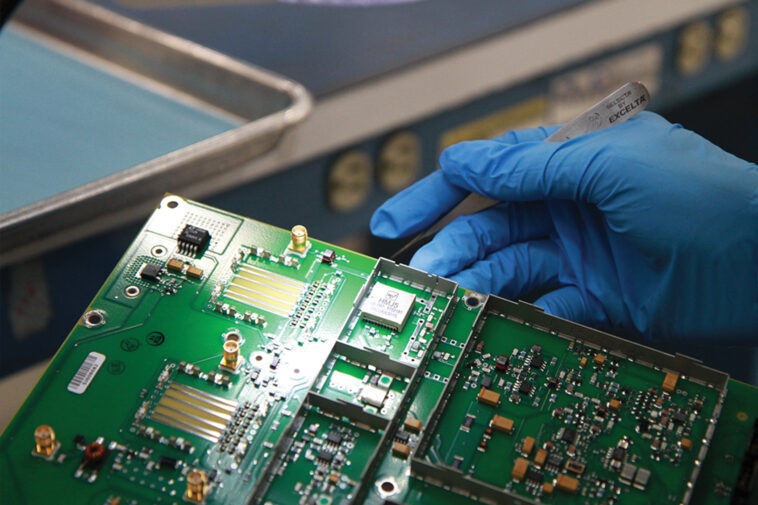

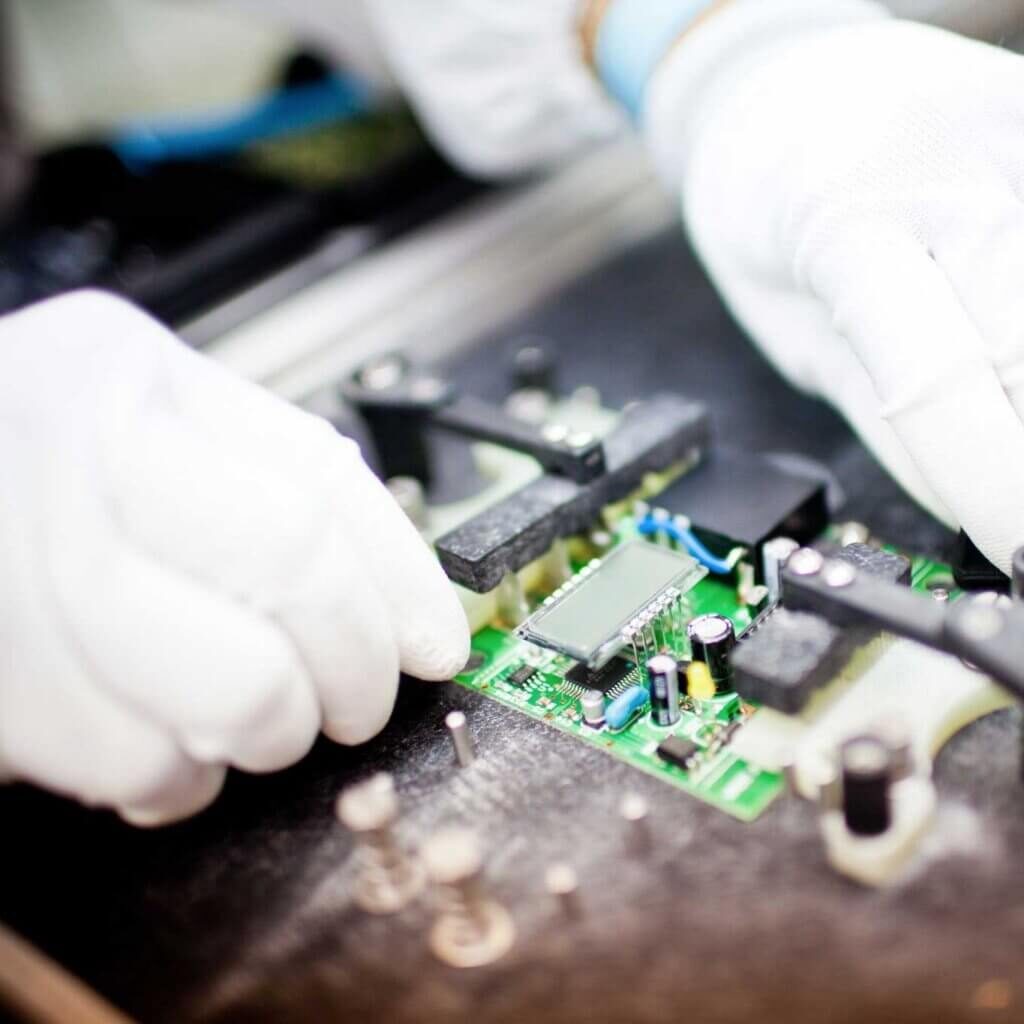

When it comes to electronics, it’s pretty safe to say that this particular business sphere is probably the most difficult one to go through if you don’t have the right manufacturer by your side. After all, electronics are really difficult to put together because you need microscopic precision and really reliable materials. Without a solid manufacturer, this is pretty difficult to pull off.

Thankfully, in today’s article, we’ll help you learn more about how to make the right choice when choosing your contract manufacturing partner.

1. Choose based on location – Try finding someone close to your business

It’s always much better to have the ability to visit the place where your product is or will be manufactured. We don’t have any particular reason for thinking this, it’s just out of convenience and safety. You can always go and see things with your own eyes, and as a wise person once said, your connections are not working unless you’re shaking hands.

This is why it’s so much better to choose someone who isn’t offshore but instead operates in your own country, or even better, your own city. Thanks to the internet, we can easily find these manufacturers based on location, but if you don’t know where to start looking for an Electronic Contract Manufacturing Partner, uetpcb.com is a website where you can learn more.

2. Check their previous experience – Look for reputable manufacturers

We’re not bashing on the underdogs but if you are looking to dive deep into the world of manufacturing, it’s best that you spend that large investment somewhere safe, and what’s safer than a company with a great reputation and a long history of manufacturing?

Some of the newer companies on the market will probably offer more competitive prices as well as a few discounts here and there, but if you really want to be sure, it’s best to go with some of the more reputable manufacturers with years of experience under their belts. On top of this, you can easily get the opinions of others for a company that’s popular, which is quite the opposite with less-known companies since you can’t easily find someone who used their service.

3. Futureproof your idea – Is the manufacturer able to scale up if needed?

Let’s say your product explodes (not literally) on the market, and the demand increases drastically, which is something that we definitely hope for by the way. You’ll need your manufacturer to scale up the production levels in a really short period of time. But, if they are unable to, simply because those are their limited equipment and man-power wise, you’ll have to switch to a new manufacturer and that’s a problem.

While switching to collaborating with someone else, there will be a massive downtime in production which can potentially mean a decrease in the popularity of your product on the market. All that you managed to build up will suddenly go down.

This is why we recommend considering an electronic contract manufacturing partner who has the equipment and manpower to scale up the production immediately when needed. Choosing based on that will futureproof your idea.

4. The price – Budget is a huge factor

Obviously, money is one of the most important resources in life, and definitely the most important one in business. Choosing based on price is nothing new and will always remain the most accurate way of choosing. Is your manufacturer operating in an area where working labor is cheaper? Are you losing a lot of money in the currency conversion? Is the higher price you are paying for a local manufacturer worth it?

All of these questions need to be answered before you choose the one manufacturer you feel is the best for your type of business. Have an accountant by your side because these things can get complicated real quick with the numbers. All in all, go for the choice that allows you to produce the most without losing a lot of money. Basically the fundamentals of business.

5. Turnaround and delivery times – Are you getting that ROI quick enough?

Your customers don’t like waiting, especially if they already paid for some of your products and now they are eagerly expecting them to be delivered at their doorsteps. How much time does your manufacturing partner need to turn your investment into a re-sellable batch? Obviously, you should choose the one that has the quickest turnaround. This is especially important during times such as a global pandemic.

6. Extra features are always a plus – Prototype designs and discount on the first batch

Will your manufacturer allow for a free prototype design? A few samples to test out the idea maybe? All of these extra features are great, and they can easily attract customers, which is why most underdogs are using them. They are always a nice plus but shouldn’t be the deciding factor.

Conclusion

Manufacturing partners are what’s going to determine whether your design will come to life in the form you imagined while creating the blueprint. This means that manufacturing partners are of huge importance so finding the right one for your business is crucial for success. That’s exactly what we helped you achieve through the content in today’s article, so feel free to check it out if you still haven’t.

As always, we thank you for the time you took to read this article and we hope that we helped you make the right business decision. Stay safe and stay productive.