Safety should be the number one priority when we process different materials and goods. If we don’t want to damage the products or injure ourselves, we need to know what is safe for processing, and what should be done with extreme caution.

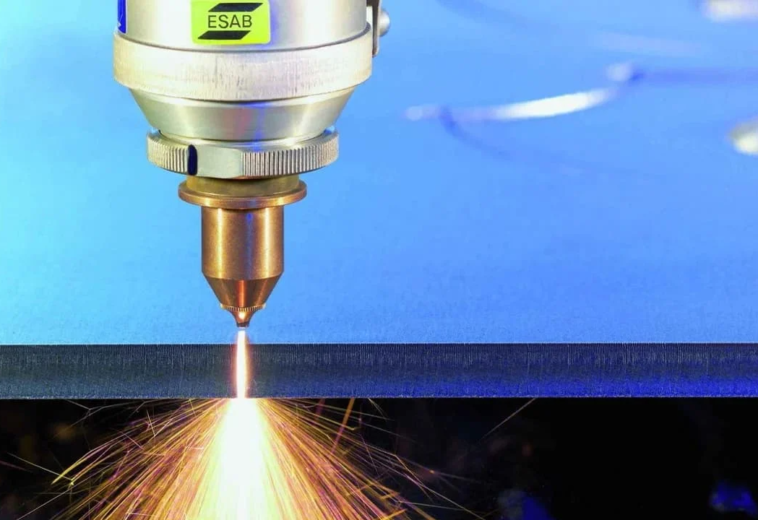

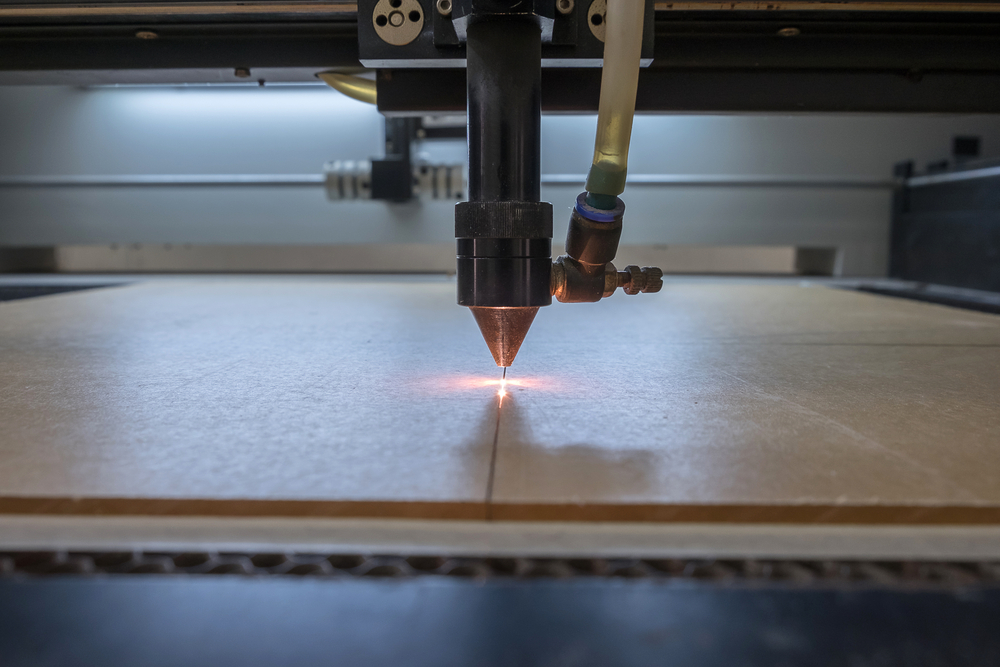

The laser cutting machines help us create new products, engrave logos, slogans, and designs, and they make the manufacturing process far better and easier. If you want to create beautiful items, if you want to improve customer satisfaction, and if you want to keep your workers safe, you should know what you can and cannot work with.

In this article, we are going to list some of the safe and unsafe materials for a laser cutting machine, and we will give you some tips on how to avoid the most commonly made mistakes when using them.

Materials that you can cut

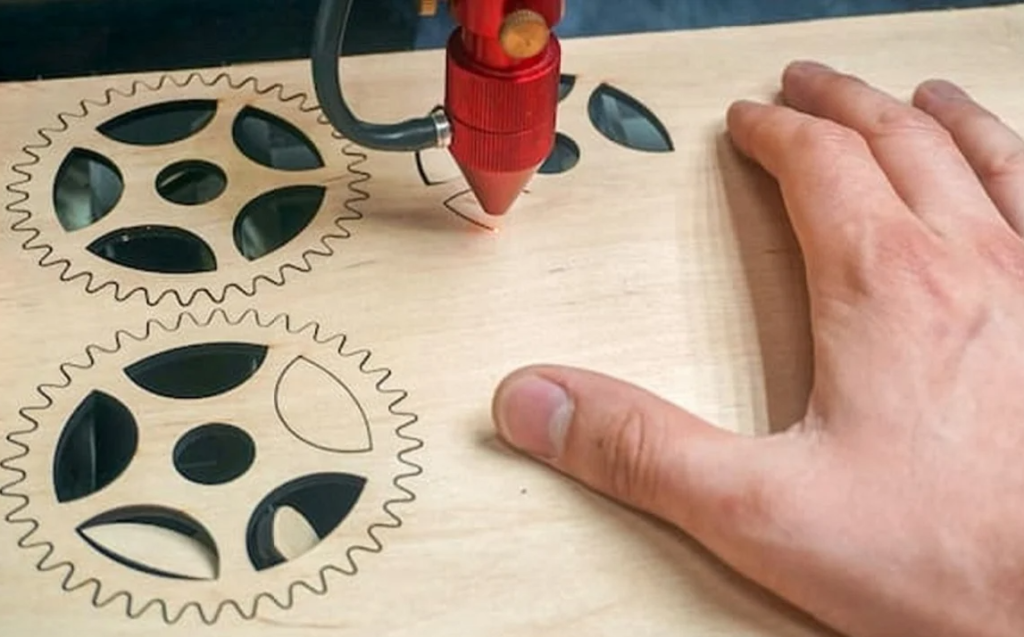

The first thing we are going to start with is the safe materials that you can easily cut using these devices. Note that when it comes to most types of wood and paper, and some types of plastic, you don’t have to worry about the dangers and potential hazards that could occur.

One thing that you should know is that if you are using a specific material, and if you are unsure if it is safe or unsafe to use, you should talk to a professional and get their expert advice.

When it comes to most types of wood, they are completely safe, but you should pay attention to the resinous types because the friction may lead to fire hazards. Be extra careful, and use the proper equipment.

When it comes to engineered, plywood, and composite, you should know that these are all safe for use, but some may be more difficult to cut than others. Some may have glue incorporated and this will make your job a bit more complex. Nevertheless, you should not have any issues or problems using them.

When it comes to cardboard, paper, or carton, you can easily cut them with laser cutting machines, and more often than not, the job will be done really fast without problems.

Note that in some rare cases, the carboard may catch fire, especially if it is too brittle or thick. Because of this, you should use proper measures, and you should look for the warning signs that something is not going right.

Cork is said to be another material that you should not worry about when using, and you should be able to cut it without any delays or problems. One thing you should remember is that some types of this material may be infused with glue, so you may have some small issues cutting through them.

Most of the types of plastic including acryl, Plexiglas, polycarbonate sheets, and polyamide are pretty safe to use and put in your laser cutting machine.

However, all of these come with a warning, and you need to pay close attention to the user guidelines. In some cases, you will be left with perfectly cut products, but sometimes you may experience discoloration and some slight damages on the edges.

You should always check if there are any burn marks and if the plastic is starting to melt. If you notice this, you should stop cutting right away.

Note that when it comes to plastic, these types are safe only if you follow the thickness regulations, and if you try to cut something thicker than allowed, it will instantly turn into a hazardous and unsafe material.

On websites like dxtech.com, you can see that the machine will make the biggest difference, and the Pipe laser cutting machine is one of the preferred ones because of the customization features it offers, along with durability, and ease of use.

Some types of foam, fabric, and leather can be cut with precision, and they are relatively safe.

However, they require constant monitoring and you need to work slowly. They can easily get damaged or catch fire if you don’t follow the guidelines.

Materials you should not process

When it comes to things you should not process, you need to know that some of these materials can be extremely hazardous. They can release fumes that are really toxic and that can do a lot of damage when it comes to the health of the professional.

In case you choose to still process them, proper equipment has to be used, and you need to know all the warning signs. Some materials may even release toxic fumes even after they are processed, so you should pay attention to the long-term consequences as well.

ABS along with milk bottle plastic easily melts when you try to process them, and in some cases, they may even catch fire. You should not use the laser cutting machine on them, and you will just waste your time and end up with a damaged product. You may even damage the device itself and you risk injuring yourself.

PVC, fiberglass, some types of carbon fiber, and ABS are known for emitting toxic fumes and gas.

You should never try to cut them with these devices, and in case you do, the worker has to be protected. You should never inhale these fumes, and if you accidentally do, you have to consult with your doctor right away.

Finally, materials including polypropylene, polystyrene, polycarbonate, and most of the types of foam are known for catching fire right away. They will either melt, get discolored, or catch fire while processing them, and they will result in an injured worker, damaged goods, or they will break the cutter.

If you are unsure what you can and cannot process, or if you don’t know what the goods are made of, you should always read the instructions for use, and you should consult with the manufacturer.

There are many different types of laser cutting machines that will help you even with the most demanding materials, but you should never ignore the safety guidelines.

Use the devices with caution, and always check the thickness of the goods before processing them. It is better to do your research on time than to risk injuries, fire, and damaged machines and goods.