Sustainability in supply chain management is a growing concern and many companies are developing strategies for reducing the environmental impact of their operations. Among the strategies often employed are using sustainable materials, such as plastic pallets, in production processes, and employing green logistics practices.

A better understanding of how sustainability initiatives are changing the way business is done can help companies develop effective and cost-efficient approaches that help reduce both their environmental impact and their bottom line.

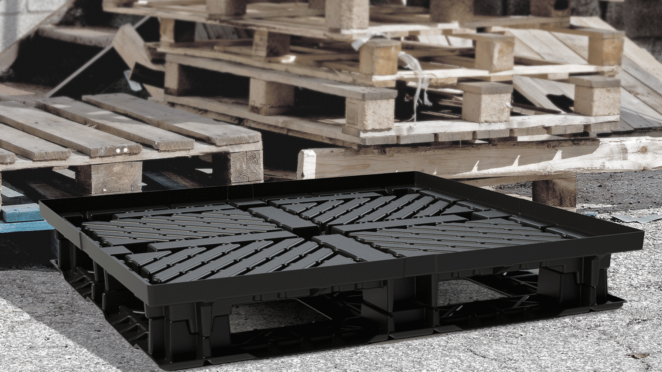

Benefits of Plastic Pallets for Supply Chain Management

Plastic pallets are steadily becoming a popular choice for companies looking to improve their supply chain management. This type of solution has multiple advantages that make it ideal for the transport and storage of products. As an innovator of sustainable practices, plastic pallets offer a host of environmental, safety, and efficiency benefits that make them an attractive option within the supply chain management sector.

Environmental Benefits:

They can be recycled multiple times without degrading performance, which helps to reduce unnecessary waste and conserves natural resources. Additionally, when compared to conventional wooden pallets, plastic pallets have been proven to have significantly lower carbon emissions over the entire product lifecycle due to their lighter mass and ability to be recycled. These green characteristics help companies significantly decrease their carbon footprint without sacrificing performance in transport or storage.

Safety Benefits:

Due to their design and robust materials used in their manufacturing processes, plastic pallets provide superior safety benefits when compared with traditional wood counterparts. They are made from non-porous surfaces which eliminate absorption problems caused by wood’s porous nature as well as prevent termite infestation or fungal growth—all of which can cause significant contamination risks such as foodborne illnesses if not addressed properly. Additionally, plastic pallet edges are rounded instead of sharp like wood boards providing user control with less chance for accidents during handling or transport operations—improving user experience as well as reducing product loss/damage due to mishandling or accidental drops/falls.

Efficiency Benefits:

With increased payloads, there are reduced accidents associated with bulk product movement – this helps optimize shipping costs and reduce environmental costs from long-distance shipping operations. Additionally, plastic pallet usage drastically cuts labor costs related to inventory storage and transit. Wasteful activities such as double handling are eliminated, allowing for more efficient loading during transit and resulting in faster cycle times. This is especially important when dealing with full truckloads of commodities that must be quickly deployed, like steel sheets used in construction or agricultural products like wheat and corn.

Regulations and Standards

When it comes to plastic pallet regulation, both state governments and the United States Environmental Protection Agency (EPA) have an oversight role in ensuring proper recycling and disposal procedures. Furthermore, there are various standards governing the use of plastic pallets that must be met. ASTM International has developed voluntary industry standards specifically for reusable plastics that ensure optimal safe use of the material when transporting goods within a supply chain context. Additionally, there are often specific standards laid out within an organization for each type of plastic equipment being used.

By understanding these regulations and standards, companies can ensure sustainable use of plastic pallets both domestically and internationally—increasingly important factors when considering relatively flat polymeric markets and global competition for packaging preferences — all while having peace of mind knowing their products meet necessary protocols laid out by government authorities or other standard-setting companies.

How Plastic Pallets are Making a Difference in Sustainability

Notably, plastic pallets are far lighter than traditional wooden alternatives; for this reason, fewer resources are required to deliver them across distances. They suffer minimal damage in transit and since they can be reused and repurposed repeatedly over a long period of time, plastic pallets also save money in the long run. Also, when these materials reach the end of their lifecycle, most manufacturers have intricate procedures in place for collecting used polymeric pallets from businesses so that those materials can be recycled into usable products again.

Furthermore, when compared to other conventional packaging materials such as cardboard boxes and polystyrene materials (which typically end up in oceans or landfills), plastic pallets offer a much more sustainable method of distribution that is good for both the planet and corporate entities alike. As climate change continues to threaten global biodiversity levels across species, using such eco-conscious methods of transportation is essential if we want to maintain planetary health.

Case Studies of Companies Using Plastic Pallets

In order to gain insight into the true value of using plastic pallets for shipping purposes, there are several case studies that highlight successful implementations of this sustainable practice. For example, UPS utilized lightweight recycled plastics in their pallet supply network and saw a significant reduction in carbon emissions due to less mass being shipped. Since then, other organizations have followed suit and achieved notable results:

- Pepsico switched to a supply chain model that included 100% recyclable plastic pallets and saved an estimated 80 million dollars each year on transportation costs.

- Coca-Cola utilized long-life plastic pallets composed of 100% recycled material and reduced the company’s overall transport costs by 10%.

- Amazon incorporated lightweight plastic pallets into their shipping processes which helped reduce their order fulfillment cycle time by up to one minute per shipment.

- Walgreens embraced cleanliness as a major selling point for their products by utilizing plastic food-grade hygienic pallets that could be washed down quickly and efficiently at loading docks before being shipped out.

These are just a few of the case studies that demonstrate how incorporating plastic pallets into a supply chain network can have notable positive impacts financially as well as environmentally. Switching from wood to plastic has proven benefits and is something all forward-thinking companies should consider carefully when assessing sustainability initiatives within their operations.

Conclusion

Plastic pallets have become an invaluable tool in sustainability initiatives for the supply chain management. They not only cut down on waste but their durability and versatility make them a cost-effective solution for businesses looking to reduce their carbon footprint. As the industry continues to embrace sustainable practices, they are increasingly becoming essential elements of any comprehensive sustainability strategy. With the help of this green alternative, businesses can take steps towards a more environmentally responsible future while improving efficiency and profitability in their operations.